Enhancing Quality Control Processes with Tal’s System Technology

Quality control is a vital component of any manufacturing industry, ensuring that products meet the required standards and specifications. However, traditional quality control processes can be time-consuming and labor-intensive, leading to potential errors and delays in the production cycle. To address these challenges, companies are turning to innovative solutions such as Tal’s System Technology to enhance their quality control processes and improve overall efficiency.

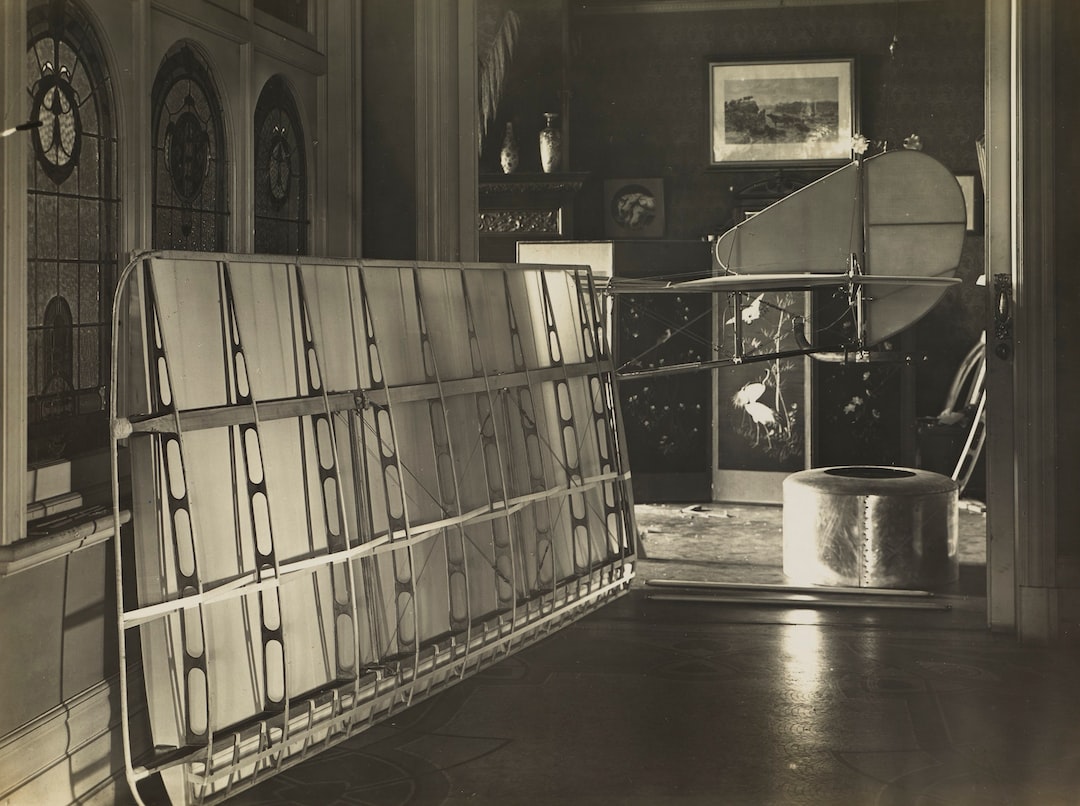

One specific example of how Tal’s System Technology can be utilized is in the manufacturing of hitzebeständige Abgasschläuche or heat-resistant exhaust hoses. These hoses are crucial components in automotive and industrial machinery, serving to channel exhaust gases away from the engine or other internal combustion systems. As they are exposed to high temperatures and harsh environment, ensuring their quality is of utmost importance.

With Tal’s System Technology, manufacturers can streamline their quality control processes for hitzebeständige Abgasschläuche, resulting in improved efficiency and accuracy. The system utilizes advanced monitoring and testing tools that enable real-time data collection and analysis. By integrating various sensors and detectors, it can track critical parameters such as temperature, pressure, and durability, ensuring that the hoses meet the required specifications.

One of the key features of Tal’s System Technology is its ability to perform non-destructive testing. Traditional quality control methods often involved destructive testing, where samples are physically damaged or destroyed during the inspection process. This can be costly and time-consuming as it requires additional manufacturing time to create replacement samples. However, Tal’s System Technology uses non-destructive testing methods, such as ultrasonic or X-ray inspection, to evaluate the integrity of the hitzebeständige Abgasschläuche without causing any damage. This significantly reduces resource waste and allows manufacturers to inspect a larger number of products in a shorter amount of time.

Moreover, Tal’s System Technology offers automated data analysis and reporting capabilities. The system can generate detailed reports based on the collected data, highlighting any deviations or abnormalities detected during the quality control process. This enables manufacturers to quickly identify and address any potential issues, ensuring consistent quality in their hitzebeständige Abgasschläuche production.

In conclusion, quality control processes are essential for maintaining the high standards required in the manufacturing industry. Through the integration of Tal’s System Technology, manufacturers can enhance their quality control processes for hitzebeständige Abgasschläuche. The advanced monitoring, non-destructive testing, and automated data analysis capabilities offered by this system contribute to improved efficiency, accuracy, and overall product quality. By adopting such innovative technologies, companies can streamline their production processes, reduce costs, and deliver reliable and durable products to their customers.

************

Want to get more details?

TAL Systemtechnik GmbH

https://www.tal-systemtechnik.de/

+49 7731 68405

Byk-Gulden-Straße 36, 78224 Singen

TAL Systemtechnik GmbH – Wir produzieren und liefern Ihnen konfektionierte Dämmstoffe nach Maß, Akustische Dämmung zur Schallisolierung, den TL flexibler Abgasschlauch hitzebeständig und diverse Schallschutzvorhänge für die Industrie.