The Evolution and Impact of Industrial Maintenance in the Manufacturing Industry

In today’s rapidly evolving world, the manufacturing industry plays a crucial role in driving economic growth and technological advancement. To ensure the smooth operation of this industry, industrial maintenance has emerged as a vital component over the years. The evolution and impact of industrial maintenance in the manufacturing industry have been remarkable, as it has revolutionized the way facilities are managed and optimized.

Traditionally, maintenance in the manufacturing industry used to rely on reactive approaches, known as “breakdown maintenance,” where repairs were only made when machines or equipment failed. However, this reactive approach led to significant downtimes, high maintenance costs, and production delays. As a result, manufacturers started to realize the need for a more proactive approach to maintenance.

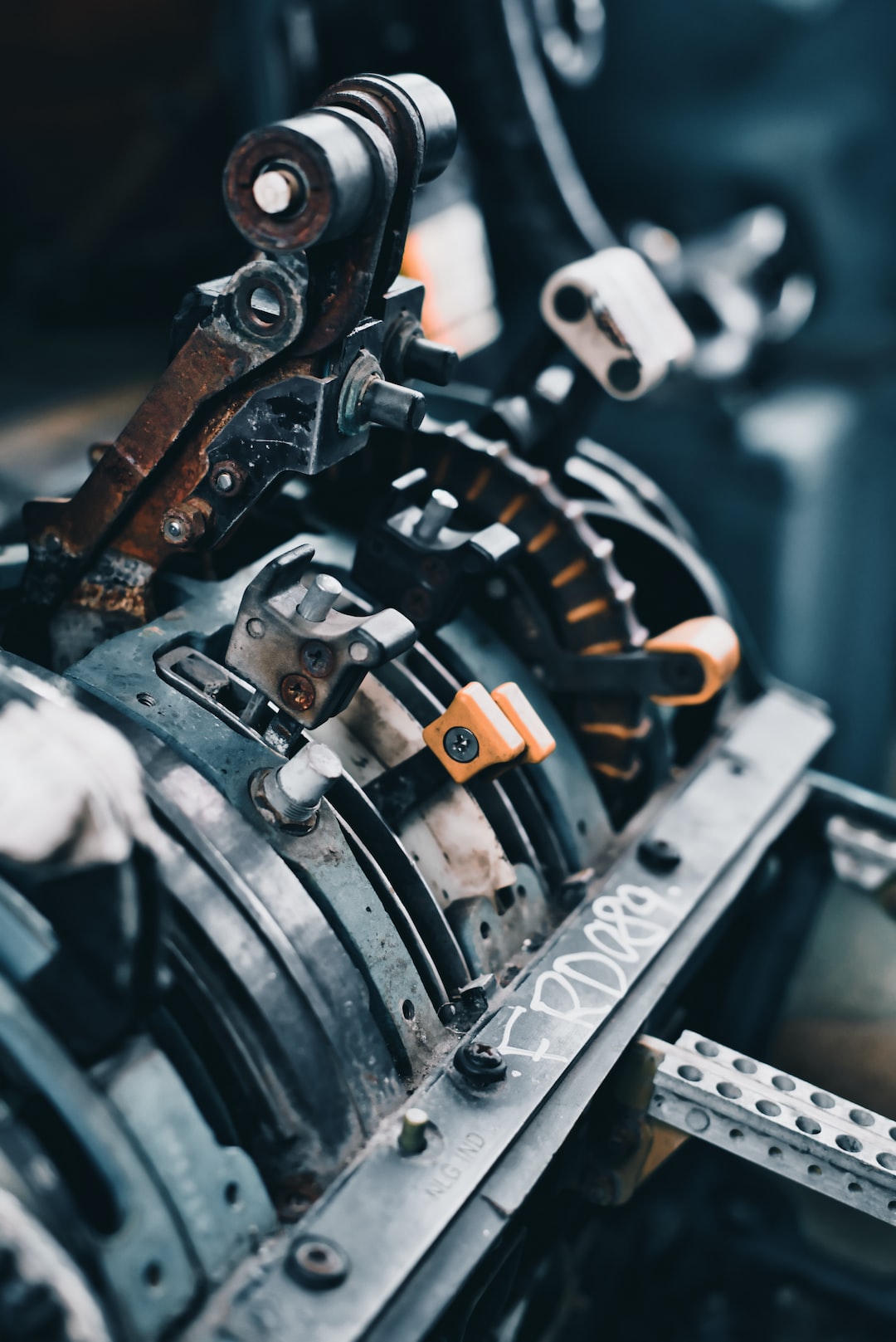

The concept of preventive maintenance took hold, based on the idea that regular maintenance checks and repairs could prevent breakdowns and improve the overall lifespan of machinery. This shift from reactive to preventive maintenance reduced downtime and enabled manufacturers to maximize their production capacities. Regular maintenance routines were established, including inspection, lubrication, and calibration, reducing the chances of unexpected failures.

As technology continued to advance, another transformative shift occurred in industrial maintenance – predictive maintenance. With the advent of sensors, Internet of Things (IoT) devices, and data analytics, manufacturers gained the ability to monitor machines in real-time and predict failures before they occurred. This allowed companies to schedule maintenance activities more efficiently, saving time and money.

Predictive maintenance utilizes machine-learning algorithms that analyze data collected from various sensors and devices installed on machines. These algorithms identify patterns and anomalies, enabling manufacturers to address potential issues before they lead to costly breakdowns. The use of predictive maintenance has become an integral part of the manufacturing industry, providing increased operational efficiency and reducing unplanned downtime.

Moreover, with the introduction of Industry 4.0 and smart factories, the capabilities of industrial maintenance have reached a new level. Now, machines and other equipment are interconnected, facilitating real-time communication between them. This connectivity not only enables predictive maintenance but also allows for remote monitoring and control, enhancing overall efficiency.

The impact of industrial maintenance on the manufacturing industry cannot be overstated. It has revolutionized operations, enabling manufacturers to improve productivity, reduce costs, and enhance product quality. By implementing regular maintenance routines, companies can extend the lifespan of their machinery, avoiding the need for frequent replacements.

Furthermore, the shift towards predictive maintenance has resulted in significant financial savings. According to a study conducted by Deloitte, manufacturers who adopted predictive maintenance strategies saved up to 12% over their preventive maintenance counterparts. Furthermore, unplanned downtime decreased by 17%, leading to increased revenue generation.

Industrial maintenance has also had a profound impact on the safety of workers in the manufacturing industry. Through proper maintenance and regular inspections, potential hazards and risks can be identified and mitigated. This proactive approach ensures the wellbeing of employees and reduces the likelihood of accidents or injuries.

Another essential aspect of industrial maintenance is its contribution to environmental conservation. By optimizing equipment and minimizing energy waste, manufacturers can reduce their ecological footprint. Regular maintenance checks help identify energy inefficiencies, allowing companies to make necessary adjustments to ensure sustainable operations.

In conclusion, the evolution and impact of industrial maintenance in the manufacturing industry have been transformative. From reactive to preventive and then predictive maintenance, the industry has embraced new technological advancements to improve operations and efficiency. Industrial maintenance has helped manufacturers reduce downtime, increase productivity, and save costs. Furthermore, it has played a crucial role in ensuring the safety of workers and contributing to environmental sustainability. Industrial maintenance continues to evolve, and it is expected to play an even more significant role in the future of manufacturing, guiding the industry towards continuous improvement and innovation.